Method and principle of carbonization of charcoal in the carbonization furnace

Method and principle of carbonization of charcoal in carbonization furnace

The carbonization furnace equipment is the important equipment of the charcoal machine, and the operation technology of the equipment is also the key to the charcoal machine production. Therefore, the correct operation of the carbonization furnace equipment to produce the charcoal machine can guarantee the quality of the charcoal, to avoid equipment failure, for their own more economic benefits.

carbonization furnace equipment carbonization methods are various, can be divided into two categories: internal combustion method, retorting method. Dry Distillation consists of three stages: low-temperature discharge, high-temperature calcination, and low-temperature cooling. The carbonization temperature should be 550 °C-600 °C. Fuel rods in carbonization furnace equipment with about 8% of water, which is the enemy of carbonization. Because the sticks are damp. The dehumidification time is 10-15 hours for the Earth Kiln and 2-3.5 hours for the kiln. The long heating time can prevent the damp cracking of the stick and ensure the quality of carbonization. When the temperature of the furnace rises to 300 °C, a large amount of combustible gas can be produced in the furnace. These gases can be heated up in the furnace. The heat source for drying can be discharged. The temperature above 400 °C is the stage of heat preservation and calcination, and the oxygen-free closed fire should be sealed. It can take spontaneous combustion cooling or water cooling. After charcoal out of the kiln to ventilate after the charcoal, to prevent carbon dioxide poisoning. Out of the charcoal should be placed in the open air for more than 8 hours, to prevent the resurgence of fire

The quality of carbonization is closely related to the raw material bar, and the density of the raw material bar should be more than 1. The simple detection method is: take a section of the formed raw material bar into the water, sink in the water, the specific gravity is greater than 1, floating is less than 1, the density of the specific gravity is high, the quality of the charcoal produced is good.

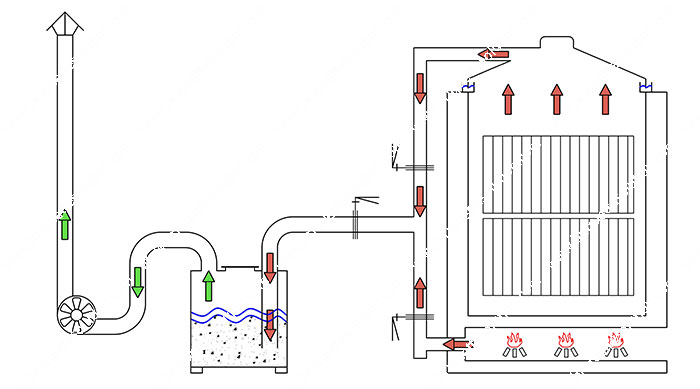

The working principle of the carbonization furnace equipment: First, the combustible materials in the gasification furnace such as Sawdust, wood scraps, etc. are ignited. After burning, the flue gas generated in the pipeline is sprayed, cooled, purified, and other processes, the combustible gas generated, as the heat source of earlier carbonization, the raw materials such as Rice Husk, Sawdust, Straw powder, fruit shell, palm shell and hemp stem in 1 #, 2 #, 3 #, and 4 # carbonization tubes in single-row or double-row combined type of fruit Shell carbonization furnace were heated and carbonized. All the flue gas produced in the carbonization process is recovered, and then the combustible gas produced is returned through the processes of spraying, cooling and purifying. In such a way, the fuel gas generated by the self is used to burn the self to achieve the effect of energy-saving. The whole production process without smoke emission, to meet the National Environmental Protection Requirements. The carbonization furnace equipment birth not only protected the environment but also may change the waste into the treasure, brings wealth to the people, which may be said to be the one-shot of many good types of equipment. The application of the Shell carbonization furnace can increase the output of the equipment, shorten the carbonization time, make the production environment smoke-free, save energy and turn waste into treasure.

The main factors affecting the carbonization and carbon yield: the type of raw materials, density, carbonization temperature. The denser the mature wood, the better. The carbonization temperature is low, the carbonization rate will be high, but the carbon smoke is big the corrosiveness increases; the carbonization temperature is high, the charcoal is friable, bent and cracked easily; the temperature range is 550 °c-650 °c, the equilibrium between friability and solid carbon content is ideal, the solid carbon content of high-quality carbon is over 80%.

The above is the method and principle of carbonization production of carbonization furnace equipment. Users should operate the carbonization furnace equipment correctly to produce machine-made charcoal, so as to make it better to produce machine-made charcoal, and the production of carbonization furnace equipment has also brought more economic benefits for the majority of users.