Waste lithium battery treatment equipment

Waste lithium battery treatment equipment

Lithium battery description:

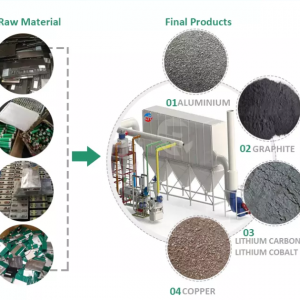

With the advantages of high voltage, high specific capacity, long life, and no memory effect, the lithium-ion battery has rapidly occupied the power source market of portable electronic and electrical equipment since its commercialization, and the output is increasing year by year. Lithium batteries are electronic consumables with a service life of about 3 years. The spent lithium batteries, if not disposed of properly, contain lithium hexafluorophosphate, carbonates, and heavy metals such as cobalt and copper, which will pose a potential threat to the environment. On the other hand, cobalt, lithium, copper, and plastics in waste lithium batteries are valuable resources with high recovery value. Therefore, the scientific and effective disposal of waste lithium batteries not only has significant environmental benefits but also has good economic benefits. The lithium battery is mainly composed of a shell, positive pole, negative pole, electrolyte, and separator. The positive electrode is composed of lithium cobalt powder coated on both sides of the aluminum foil current collector by PVDF which plays the role of adhesion, and the negative electrode is composed of carbon powder bonded on both sides of the copper foil current collector. At present, the research on the recycling of spent lithium batteries mainly focuses on the recovery of cobalt and lithium, which have a high value. In order to alleviate the problem of resource shortage and environmental pollution caused by rapid economic development, it has become a global consensus to recycle waste materials.

The copper (about 35%) in the anode of mobile phone lithium battery recycling equipment is a widely used and important raw material, and the carbon powder adhered to it can be used as plastics, rubber, and other additives. Therefore, the effective separation of the anode materials of the spent lithium battery can promote the recycling of the spent lithium battery and eliminate the corresponding environmental impact. The common recycling methods of waste lithium batteries include hydrometallurgy, pyrometallurgy, and mechanical physics. Compared with the wet method and fire method, the mechanical physical method does not need chemical reagent and consumes less energy. It is an environment-friendly and efficient method. Based on the structural characteristics of the anode of lithium battery, the separation and preconcentration of anode copper, aluminum, and carbon powder were studied by the combined process of crushing screening and air separation.

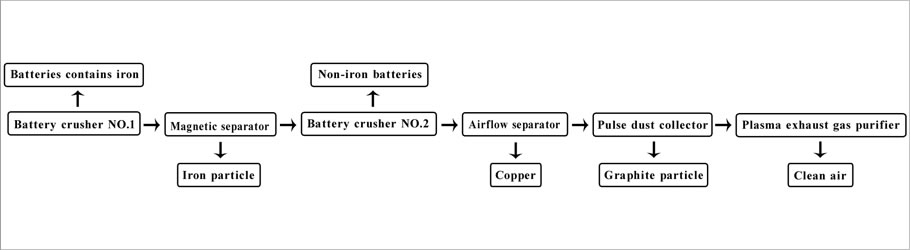

How Waste Lithium Battery Recovery Equipment Works:

Based on the positive and negative electrode structure of lithium battery and the material characteristics of copper and carbon powder, the technology of Shredder, wind separator, hammer crushing, vibrating screen, and air separation was used to separate and recover the anode materials of waste lithium battery.

Features of waste lithium battery recovery equipment:

1. The utilization of copper and carbon powder in the anode materials of waste lithium batteries can be realized by the combined process of hammer crushing, vibration screening, and air separation.

2. The separation of carbon powder and copper-aluminum foil can be realized by hammer crushing of positive and negative electrode materials, and then the copper foil and carbon powder can be separated by vibrating sieving based on the difference of size and shape between particles. The results of hammer vibration stripping and screen separation show that.

3. The equipment is mainly used by lithium-ion battery manufacturers to separate the positive and negative electrode materials from the spent lithium batteries for recycling purposes. The complete set of equipment operates in the negative pressure state, without dust leakage, and the separation efficiency can reach over 98%.

Working principle: first, the whole lithium battery is mechanically disassembled, the shell is separated, the diaphragm is separated, and then the positive and negative grade raw materials are crushed by a coarse crusher to less than 10 mm, and then into a fine particle crusher for stripping and crushing, after entering the fine powder classifier separation processing, the tail ash is collected by the back passage cyclone separator and the pulse dust collector.

Common lithium battery categories:

The lithium battery can be divided into several categories (soft-package lithium battery, plastic-shell lithium battery, aluminum-shell lithium battery, 18650 galvanized-shell lithium battery) according to the different materials of lithium battery, we make processing production process according to its characteristics.