Ways of recycling waste printed circuit board

recycling and treatment of waste printed circuit boards: at present, direct burial, incineration, water washing and pyrolysis are commonly used in many areas, but toxic substances are released, which can easily cause serious secondary pollution of air or soil and other environment.

Environmental protection policies do not allow this or restrict these treatment modes. The international method of recycling waste recycling-machine-p.html target='_blank'>Printed Circuit Board is physical method, which has the advantages of low environmental pollution, high comprehensive utilization rate and high added value. It is the development trend of electronic waste treatment in the future. Its disadvantage is that the treatment cost is slightly higher than that of incineration or washing.

Due to the toughness of waste printed circuit boards (PCBs), it is difficult to separate metals from nonmetals through one-time crushing. Moreover, there are many kinds of substances in waste printed circuit boards, and the separation and decomposition process is complex. These characteristics determine that the recycling of waste circuit boards is difficult.

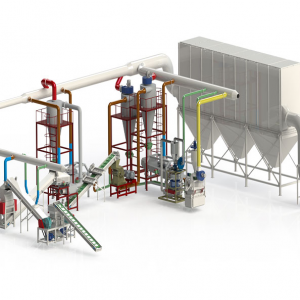

Circuit board recycling equipment is a set of scrap circuit board disassembly and decomposition into metal and non-metal process. Circuit boards with electronic components are removed after tin removal and disassembly (components are classified and treated separately). Through coarse crushing, iron removal, and fine crushing, the circuit board completes the dissociation of metal and non-metal, forming a mixture of metal and non-metal, and entering the air flow specific gravity screen to extract most of the metal.

The fine metal (about 2-5% in content) is contained in the circuit board fiber powder screened out by air flow specific gravity screen, and then enters the electrostatic separator to extract the remaining fine metal. The metal recovery rate can be as high as 99%.