Description

Product introduction

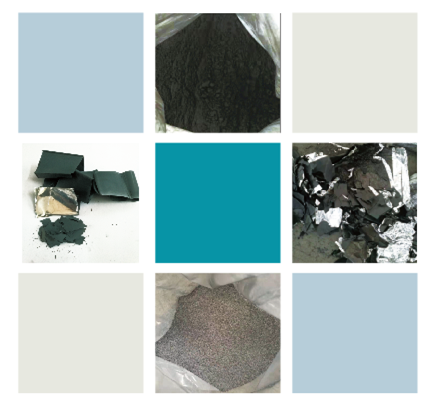

The production line is used for the recovery and reuse of the waste cathode material (positive plates) of lithium battery. The final products, Aluminum particles and positive material powder, are obtained by crushing and seperation process.Production line process

Scrap positive plates are feed to the shredder machine for shredding, the shredded ones enter the crusher machine, the crushed materials enter the classifier machine for primary separation, the mixture of Aluminum particles and black powder enter the linear screen for screening, Aluminum particles comes out from the upper layer, the lower layer is positive material powder, the middle layer is the mixture of aluminum particles and positive material powder, this mixture material enters the grinder machine for grinding,Then the material enters the material collector, then to the rotary vibrating screen for final separation.

Features of machine

1. Multiple crushing and screening to achieve complete recovery

2. Closed operation of production line

3. Using pulse bag filter, no dust will be produced in the production process

4. PLC control system is available

Technical parameters

Model

Production capacity(kg/h)

Total Power(KW)

Space required(m2)

ZJ-500

400-600

92

40

ZJ-1000

800-1000

125

85