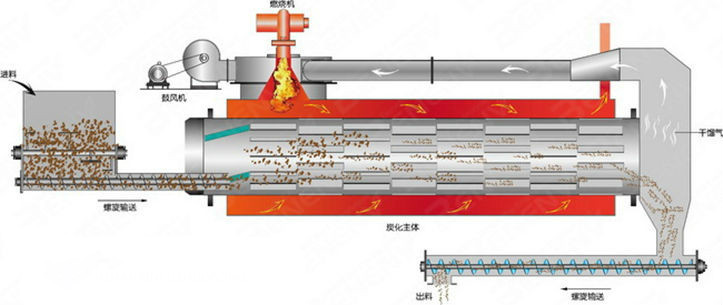

Working principle of continuous charring furnace

Continuous carbonization furnace is an epoch-making product to eliminate the old type of hoisting furnace. The carbonization time is shortened from a few days to a few hours, which greatly improves the working efficiency, the processed charcoal products are much more durable and aesthetically-pleasing than the older models

Carbon monoxide, methane, oxygen, and other combustible gases produced during the carbonization process are reasonably recovered, purified, and cyclically burned. That is to say, the problem of environmental pollution caused by the thick smoke produced by the ordinary carbonizing machine in the carbonizing engineering is solved, as well as the problem of the heat energy needed by the equipment is solved, self-supply and self-sufficiency are fully realized, and the continuity and economy of the equipment are improved, making full use of the surplus of agriculture and forestry, changing waste into treasure, lessening the contradiction between supply and demand of forestry resources in our country, and making more contribution to the greening environment.

Working principle of continuous charring furnace

The carbonization machine is the first material through the gasifier combustion, produce smoke, through the smoke purification system to worry about wood tar smoke and other gas impurities, the smoke into the carbonization machine for combustion, to a certain temperature, the carbonization machine adds the material which needs carbonization, through the pipeline transmission, causes the material to burn in the carbonization machine, the organic matter combustion needs to satisfy three points: the quantity of heat, the oxygen, and the organic matter, because the carbonization machine is almost the airtight space, meets the oxygen-deficient demand, so that the material in the carbonized internal temperature of 800 degrees, through the internal conveyor speed of the carbonized adjustment will not be burned into ash, only burned into carbon. After the treatment of flue gas purification, the flue gas from the burning material in the carbonizing machine is returned to the carbonizing machine for combustion, so that the heat energy of the machine can be continuously operated to achieve smokeless, environmental protection and continuous effect. Finally, through the transport of the cooler, the carbon is cooled, so that the temperature when the carbon comes out is only 50-80 degrees. In the process of transporting the carbon after it comes out because the carbon is in full contact with the air if the material density is large and relatively thick, although there is no open flame on the surface, there could be sparks in the core, or it could spontaneously combust. Need to add spray equipment, the carbon out of the second cooling, to completely eliminate the fire.

Application scope of continuous charring furnace

The continuous carbonization machine can carbonize materials in a very wide range. The continuous carbonization machine can combine Sawdust, Rice Husk, peanut Husk, plant, Bark, Straw, organic matter, the ideal equipment for retorting, non-oxygen carbonization and high carbonization rate of wood materials with carbon content (diameter less than 15mm) such as hemp, Walnut Shell, Coconut Shell, Palm Shell, Sawdust, etc. At the same time, it can pyrolysis garbage, waste tires, Lignite, coal-based, blue carbon, active coke, magnesium oxide, sodium oxide, and other chemicals.

Advantages of continuous charring furnace

1. This equipment adopts the intelligent control system to save the labor force and move towards the development of high efficiency/automation/intelligence. 2. Breakthrough the difficult problem that the traditional carbonization equipment can not continuously carbonize 3. The process of co-production of Carbon/gas/oil/Fertilizer is realized, which solves the defects of traditional high energy consumption/pollution/low efficiency. 4. Tar/wood Vinegar Liquid and combustible gas can be collected automatically in the carbonation process to realize the efficient utilization of renewable energy

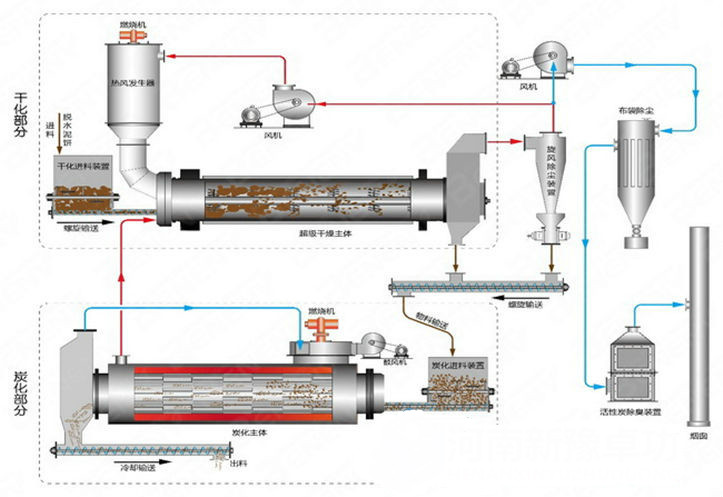

Continuous charring furnace component:

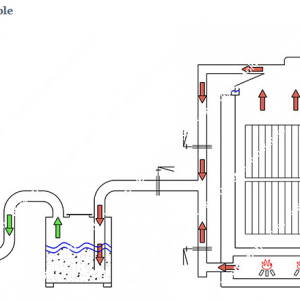

The equipment of the carbonization production line includes a carbonization machine, gasifier, fume processor, combustible gas purifier, combustible gas condenser, and induced draft fan. The continuous carbonization furnace is a new type of high-efficiency, energy-saving, and environment-friendly carbonizing equipment, which is suitable for the carbonization of small powder like Sawdust, Rice Husk, Straw, sludge, garbage, etc. , is the entire process does not produce harmful gas, does not pollute the environment.

Normal operation of continuous carbonization furnace

1, charring machine just started (feeding first) heating, the need for heat source heating charring machine.

One is to use the hot gas produced by the reverberatory furnace to carbonize the coal in order to increase the temperature.

The other is to use a gasifier device, the straw gas is ignited through the Gasifier, and the combustible gas produced by gasification is burned and carbonized, the gasified Straw is converted into the carbonized carbon powder through the carbonized carbon powder output device, and the combustible gas is recovered through the wood tar recovery device

2, carbonization temperature to a certain temperature, the combustible gas generated inside the dust separator to dust separation, after dust separation of combustible gas through the Wood Tar recovery device recovery.

3. After the carbonization heating self-produced gas, the reverberatory furnace heating or gasifier gas production device stops working at this time, and the preliminary heating equipment work is finished.

4, carbonization about 0.5-1 hours (time temperature is different) after carbon powder from carbonization into slowly carbonization carbon powder cooler and from the cooler outflow, equipment production can be continuous blanking.

5, wood tar is an important chemical raw material, wood tar contains more than 300 kinds of the chemical element, this equipment will automatically discharge wood tar.