Reuse and recovery of waste power lithium ion battery

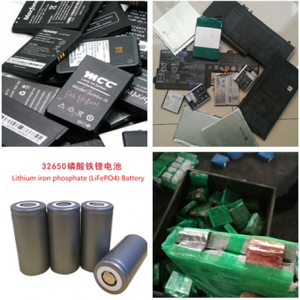

It is understood that power batteries are mainly divided into lithium ternary batteries and lithium iron phosphate. The main components of both batteries contain lithium, cobalt, nickel, manganese and other heavy metals. Among them, cobalt and nickel are rare mineral resources in China and are very precious.

There are different methods of recycling heavy metals from waste power batteries at home and abroad. In foreign countries, useful metals are extracted mainly through pyrometallurgy (wet separation and purification), pyrolysis (wet purification), crushing (pyrolysis), distillation (pyrometallurgy), etc.; while in China, pyrolysis (mechanical disassembly), physical separation, hydrometallurgy and other processes are usually used to recover and treat waste lithium battery in China.

As the composition ratio of power battery is generally more complex, different types of batteries have different recovery rates, and different types of batteries also have different recovery processes. For example, pyrometallurgy is usually used to recover cobalt and nickel, but the effect on lithium is poor. Hydrometallurgy is quite effective for recovering metal from lithium iron phosphate battery.

It is reported that the main mode of waste battery treatment in Germany is to establish a market-oriented system with government legislation, producers taking responsibility, and establishing funds. The United States is mainly based on the sales channels, which are constrained by the deposit system. Japan and China are relatively close, mainly in the recycling mode, with enterprises as the main body to participate in lithium ion battery recycling.