Hydrometallurgy: high recovery rate of valuable materials for lithium battery

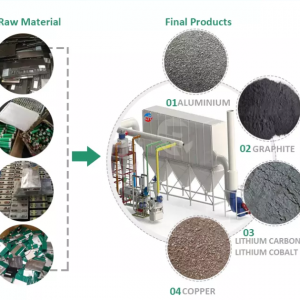

The recovery process of power battery can be roughly divided into three steps: pretreatment material recovery screening preparation. In the pretreatment stage, the battery is mainly discharged, disassembled, crushed and sorted to separate the metal shell and electrode materials of the battery; the material recovery stage is the key link of the power battery recycling, mainly through dissolution, extraction, precipitation, electrolysis and other ways, various valuable materials are classified and recovered in the form of single substance, compound or mixture, generally including physical recovery Chemical recovery and biological recovery.

Due to the high energy consumption, low recovery rate and certain waste pollution, biological methods are still in the initial stage, and various aspects of technology are not mature, not suitable for wide use at this stage, but the development potential is great. Therefore, more chemical methods are used at present. Although the cost is high, the high cost in return is a high degree of automation and high recovery rate, and the pollution is low.

The content of high-value metals in ternary batteries is high, so the recovery efficiency of valuable materials by wet recycling process is higher and the benefits are obvious. According to the relevant calculation, the average income of recycling ternary battery per ton by wet recycling process is more than 17000 RMB, and the treatment cost is about 15000 RMB. Therefore, the income of recycling ternary battery per ton by wet recycling process is about 3000 RMB. After recycling valuable materials, it is necessary to adjust the proportion of materials in the solution by adding chemicals to prepare positive and negative electrode materials for lithium-ion batteries.